Projects

Security Lighting Upgrade

Problem:

Replacement of high consuming energy mercury lighting fittings

Solution:

Replaced with low energy consuming lighting fitting leading to 300% reduction in energy cost

Installation of MV/LV Transformers

Problem:

Lack of alternative power supply in case of power outage.

Solution:

New installation to integrate alternative power source to guarantee uninterrupted power supply.

Gas Leakage Detection

Problem:

Difficulty in monitoring leakage of hazardous chemicals.

Solution:

Effective monitoring, control and supervision of leakage for prompt rectification.

Factory Wide Electrification

Problem:

To replace high energy consuming lighting fittings.

Solution:

Low energy consuming lighting fittings (LED) were provided with equal illumination, leading to almost 50% reduction in energy cost.

Energy Motor Installation

Problem:

Replacement of low efficient electric motor.

Solution:

Replaced with highly efficient energy savings electric motor with a 30% annual energy savings.

Generator Installation

Problem:

Due to high cost of diesel, poor quality and non-availability of utility power supply, a dual fuel generator that uses both gas and diesel.

Solution:

Improved power generation and reduction of downtime in changing from diesel to gas generator and vice versa.

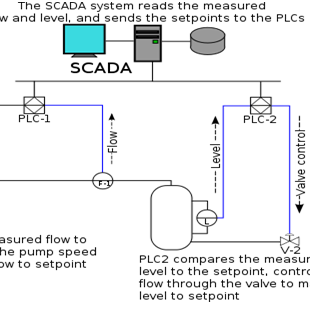

Flow/Energy Meter Installation with Scada

Problem:

Lack of information about fuel consumption and engine efficiency.

Solution:

Scada solution helped to capture real time fuel consumption and engine performance/efficiency.

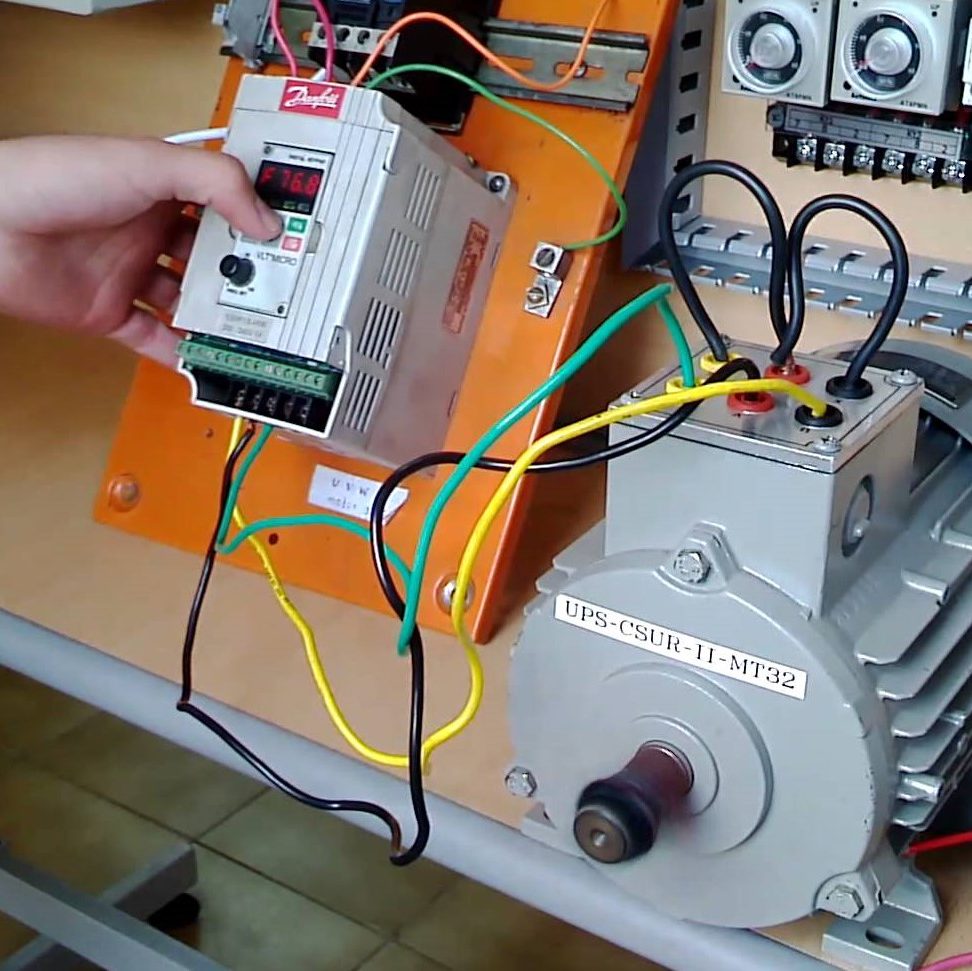

Energy Motor and Variable Frequency Drive Installation

Problem:

Inefficient motor and drives which led to increase in energy costs.

Solution:

Replaced inefficient electric VFD drives and energy motor from ie1 to ie4 which improved energy saving by an average of 45%.

Installation of 33/11kv Substation

Problem:

Old and unsafe equipment which could lead to accident and/or near miss.

Solution:

Replaced with new equipment with remote access to reduce unauthorized access to the substation and also equipped with effective and efficient meters for real time energy consumption and data collection.